You can see the difference

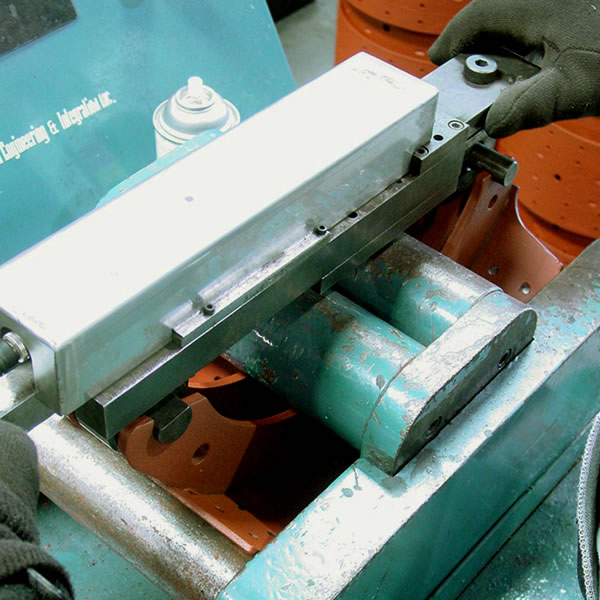

BRAKE RELINING PROCESS

Learn in-depth information on ECBR's Extensive Process by clicking each photo below

___________________

STAY INFORMED

Sign up for our email program to stay up to date on news and events:

___________________

Sign-Up Now

5812 Curlew Drive

Norfolk, VA 23502

Toll Free: 800.552.2005

© 2020 East Coast Brake Rebuilders

All Rights Reserved.